With any tuner system, on-wafer calibration down to the probe tips is needed. Additionally, the end of the cable of the Keysight N5291A frequency extender needs to be calibrated to the input of the tuner. This coaxial calibration characterizes the insertion loss of the tuner in different locations around the Smith chart.

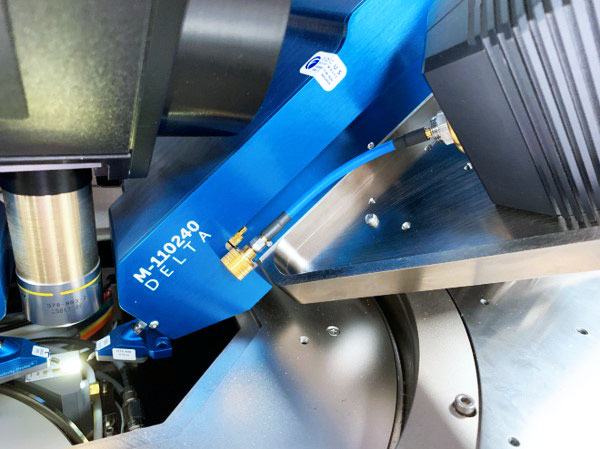

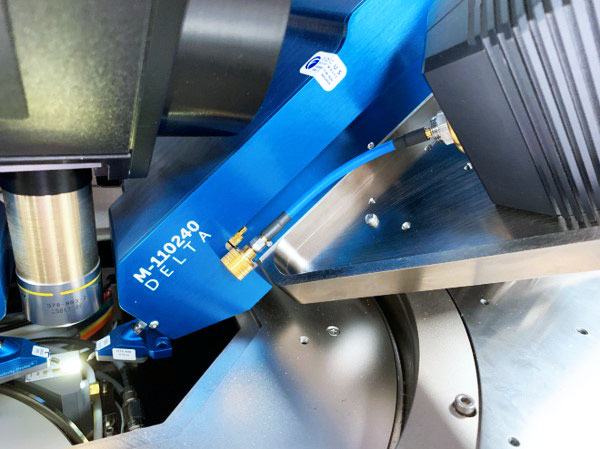

FormFactor’s millimeter-wave load-pull solution uses a short 10 cm cable from the Keysight N5291A frequency extender to the tuner input. This maximizes the available power. The cable is semi-rigid to prevent phase change error due to cable movement.

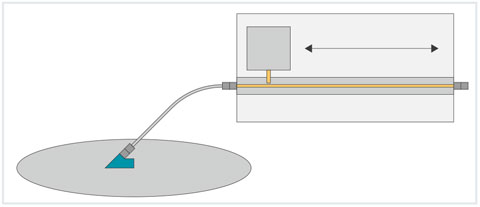

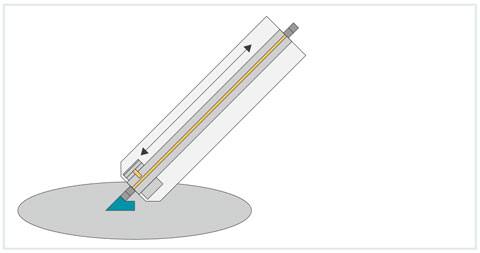

To connect a coax standard to the end of the cable, the Keysight N5291 frequency extender can easily unclamp and slide back via quick release mechanism. For thru calibrations the extenders can be lifted off and brought together to add a thru standard between the two cables.

To connect a coax standard to the end of the cable, the Keysight N5291 frequency extender can easily unclamp and slide back via quick release mechanism. The cable is semi-rigid and provides highest phase stability.

Full Thermal Range – Exclusive RF TopHat with Probe Window

With 5G devices powering the vehicle to everything (V2X) market there is a need for EMI and light-tight testing at a wide temperature range, including tests down to -40°C without a build-up of frost and condensation.

With FormFactor’s patented RF TopHat (available for CM300xi, SUMMIT200, Summit 12000 and Elite 300), the solution has full thermal capability from -60°C to +125°C. The RF TopHat was designed to minimize cable lengths, prevent stiction which impacts motorized positioner accuracy, and maintain a dark, shielded and frost-free measurement environment.

The exclusive I.T.O. coated TopHat window allows easy setup and tracking of probes without having to open the MicroChamber. The window is always shielded, always frost-free and includes a cover for dark measurements. The patented FlexShield interface enables resistance-free and highly accurate probe positioning.

The setup can be converted between TopHat and non-TopHat to meet different test requirements.

RF TopHat with I.T.O. coated window for easy setup of probes in an EMIshielded and frost-free environment. A cover enables dark measurements. |

The patented FlexShield interface enables resistance-free and highly accurate probe positioning. |

Performance Results – Tuning Range

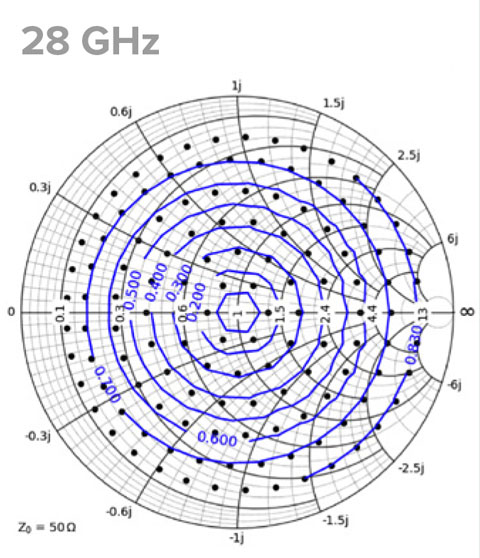

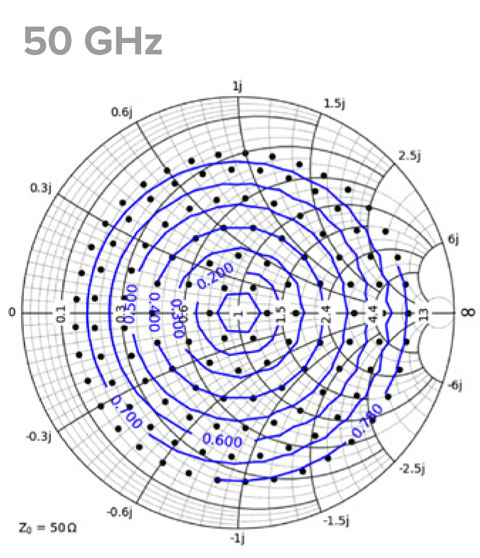

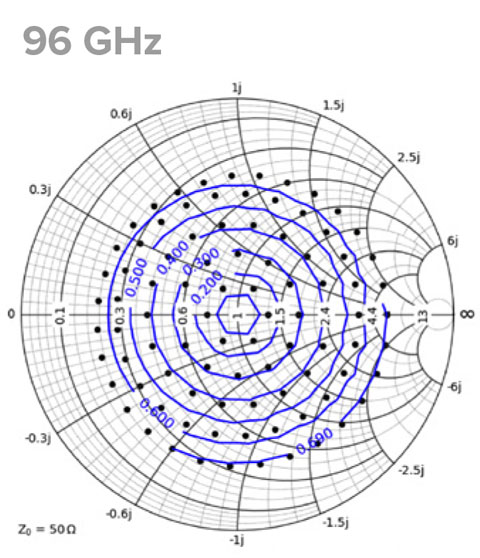

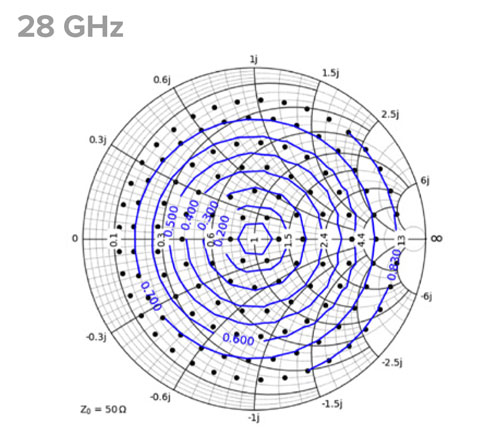

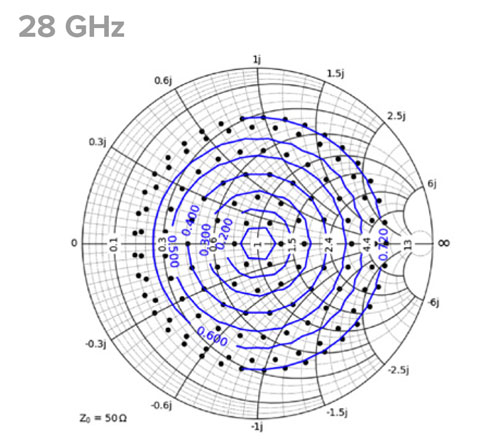

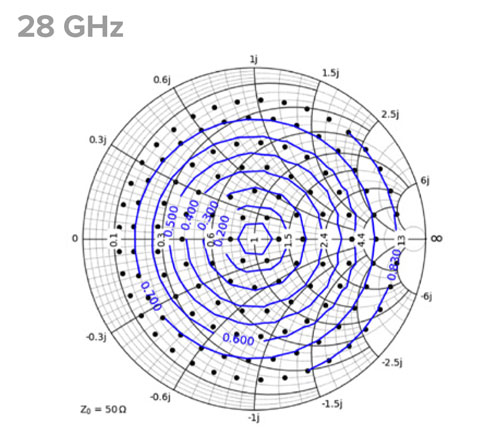

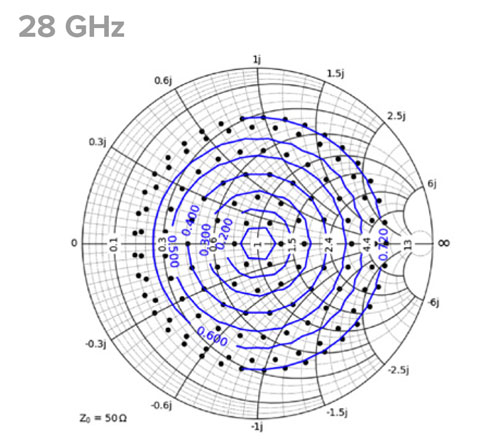

A straight, very rigid and short cable that connects the tuner with the probe inside the TopHat provides very high phase stability. Figures 8 and 9 show that the impact of this cable on the tuning range is minimal.

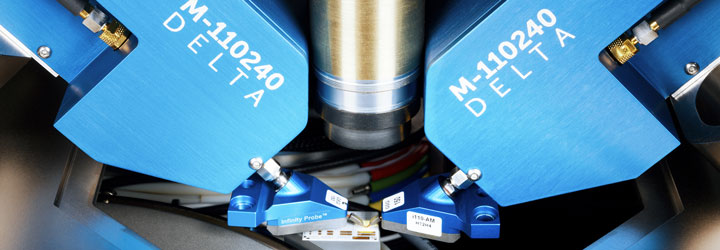

The setup uses the DELTA Tuners from Focus Microwaves with FormFactor’s Infinity Probes, fully integrated into a SUMMIT200 probe station with MicroChamber and RF TopHat, and with the N5291A frequency extenders from Keysight. In this example measurement at 28 GHz, Γmax ranges from 0.84 without TopHat, to 0.74 with TopHat. The compromise for a fully shielded environment is only less than 0.1.

Figure 8: Tuning range at 28 GHz without RF TopHat. Γmax= 0.84, Γmax_360deg= 0.79 |

Figure 9: Tuning range at 28 GHz with RF TopHat. Γmax= 0.74, Γmax_360deg= 0.7 |