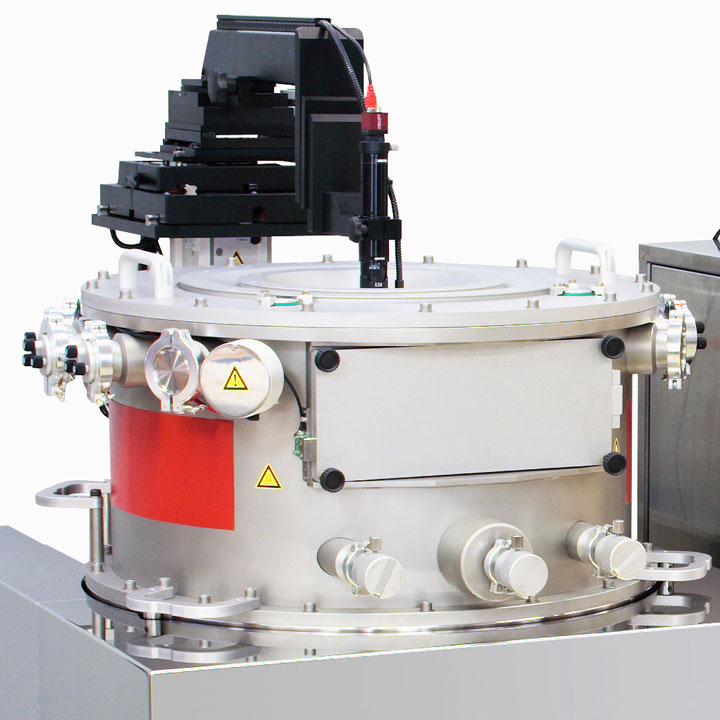

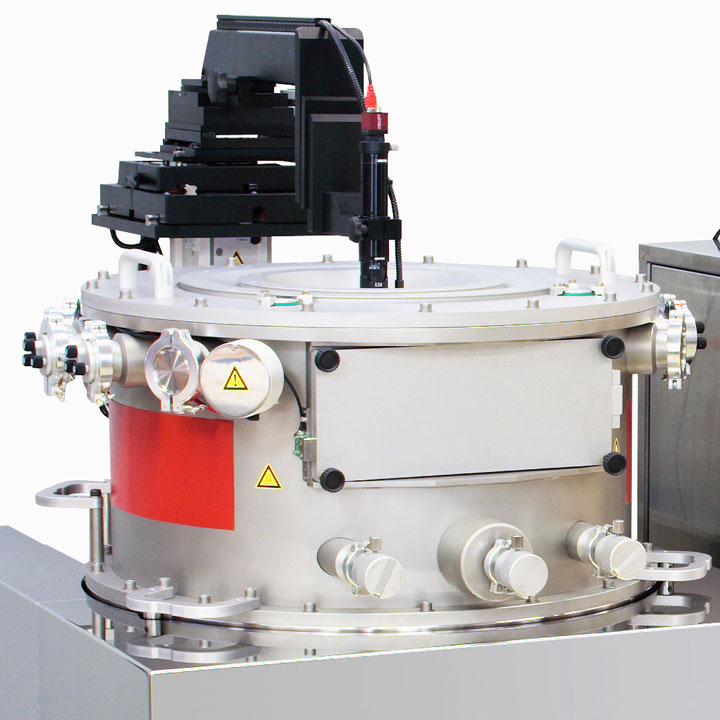

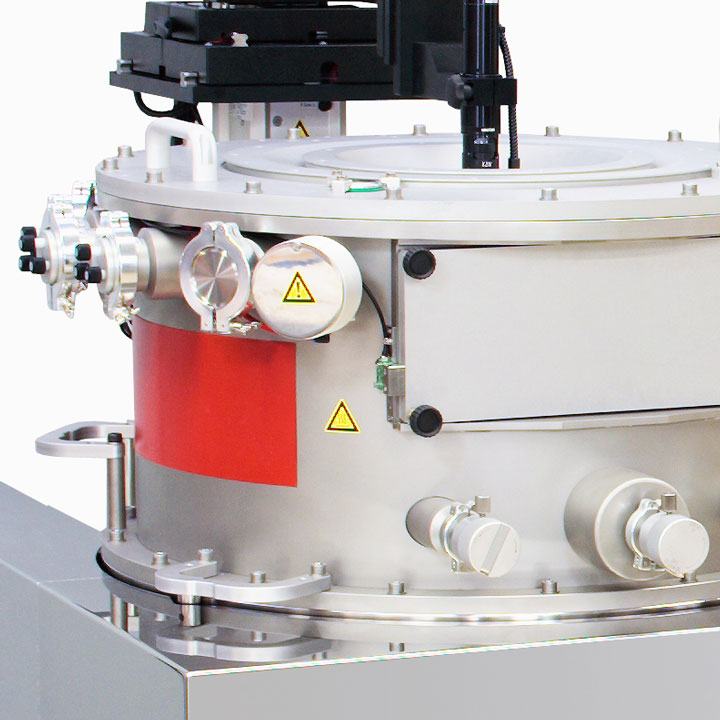

PAP200

200 mm semi-automated vacuum and pressure probe system

200 mm semi-automated vacuum and pressure probe system

Looking for customer support? Ready to learn more about our products and services?

Contact Sales TodayReceive product updates and event notifications

Subscribe to Our Newsletter

Semi-Automated Wafer Probing in a High Vacuum or Overpressure Environment

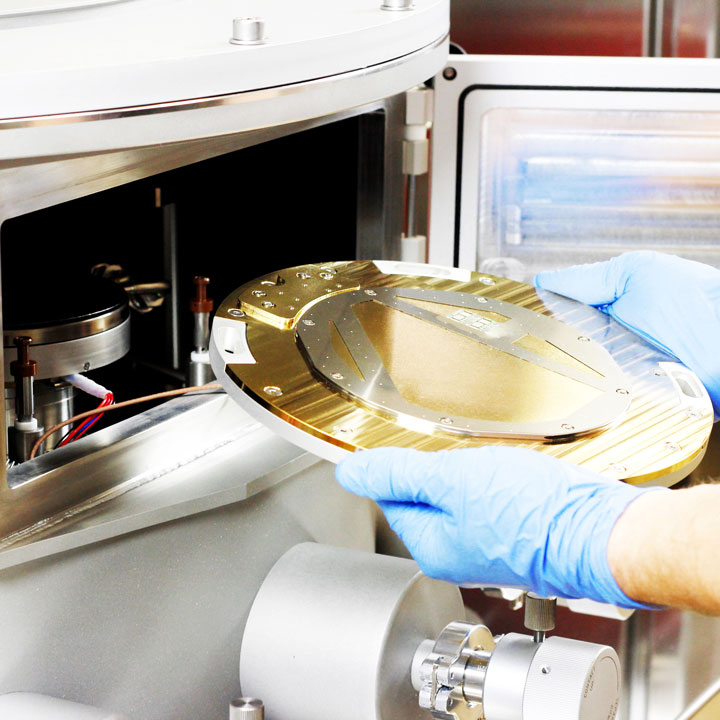

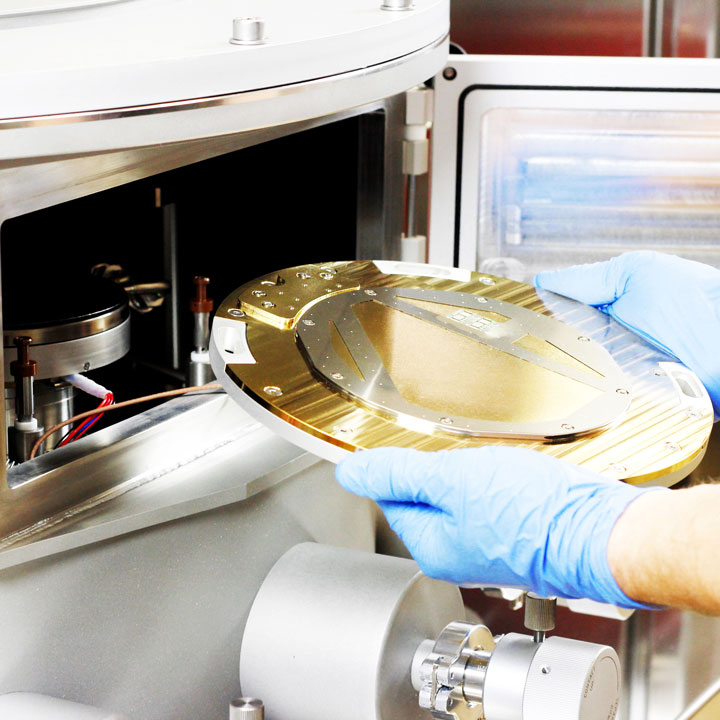

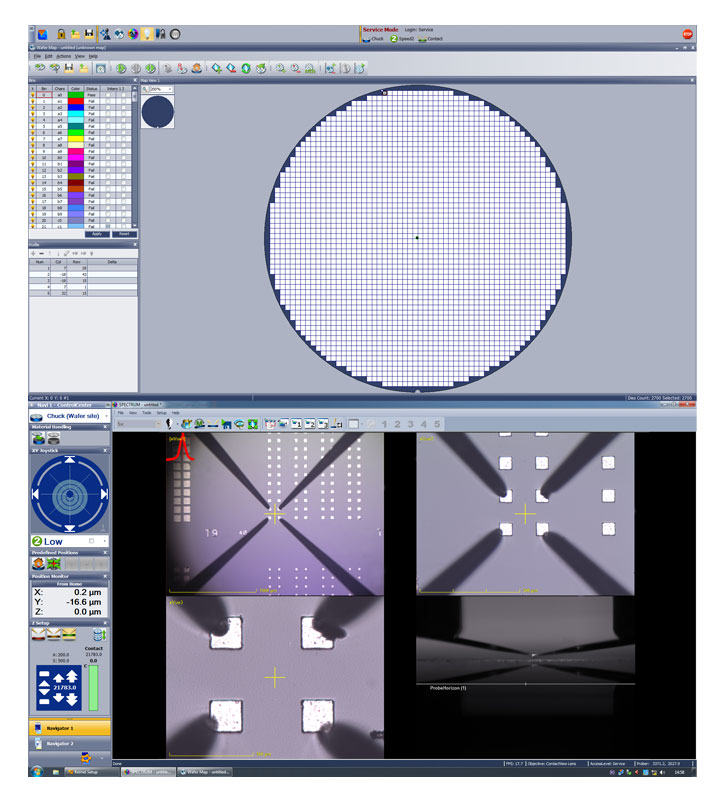

The PAP200 is a highly-precise semi-automated probing solution for wafers and substrates up to 200 mm in a vacuum environment down to < 1×10-5 mbar or in an overpressure environment up to 4.0 bar (abs.). Designed for industrial environments and major research facilities, it supports MEMS tests and a wide range of other applications.

The PAP200 supports multiple optical instruments like IR radiation sources (black bodies). Up to eight probe positioners and/or a probe card can be integrated.

SourceOne – Certified Pre-Owned Equipment

You want the best price-performance ratio for your wafer probe station? With our Certified Used Equipment we have an attractive option for you.

SourceOne – Factory Refurbishment Program

Extend the use of your probe station for up to another 15 years with our Factory Refurbishment Program.

SourceOne – Trade In / Buy Back Program

We'll take your probe station back for a credit note.

Receive product updates and event notifications

Subscribe to Our Newsletter