Quantum computing is no longer the technology of tomorrow, it’s here, growing at an unprecedented pace. By 2030, this industry is expected to surge to a staggering $125 billion, driven by transformative applications in drug discovery, risk management, cybersecurity, and advanced material design. But behind the headlines and projections lies a critical question: how do we scale quantum computing power while ensuring performance and reliability?

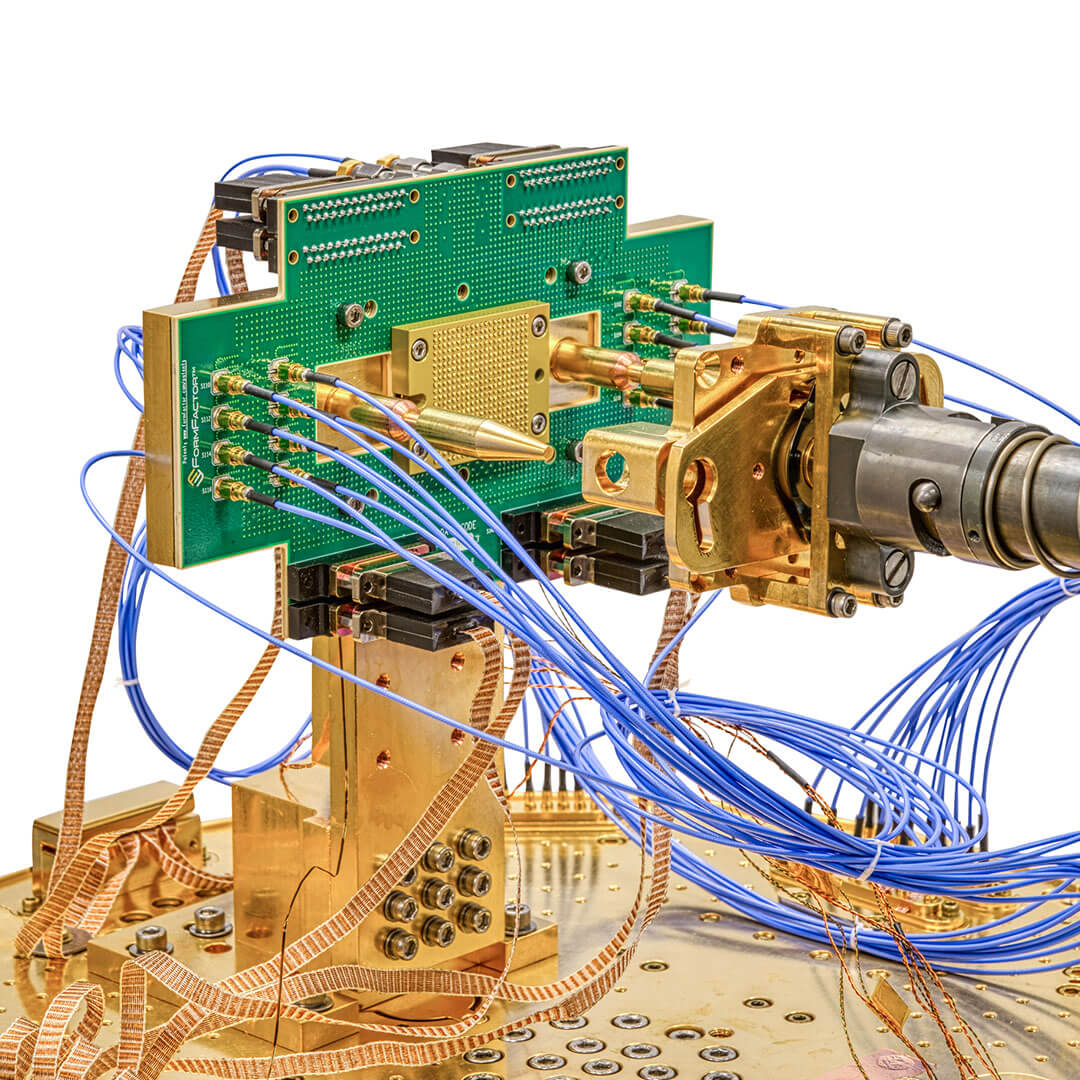

The answer starts at the die level. Enter the FormFactor PQ500 Cryogenic Probe Socket, a revolutionary solution redefining how we test quantum ICs at temperatures as low as millikelvin (mK). This innovation is more than just a technological milestone; it’s the key to unlocking the true potential of quantum computing.

The Challenge: Testing at the Edge of Physics

Quantum Integrated Circuits (ICs) are the building blocks of quantum systems, yet they demand an entirely new approach to testing. Traditional methods fall short in the face of challenges like ultra-low temperatures, precision alignment, and the need for reliable, real-world performance data. Without robust die-level testing, scaling the number of qubits—essential for quantum advancement—becomes prohibitively expensive and inefficient.

Imagine trying to detect imperfections on a single strand of silk under freezing conditions. Now multiply that complexity across an entire quantum IC, and you begin to grasp the enormity of the task.

This is where the PQ500 comes in, providing a breakthrough solution that allows engineers to probe, measure, and validate IC performance directly on the silicon—saving time, reducing costs, and accelerating innovation.

The Solution: Redefining Die-Level Testing

At its core, the FormFactor PQ500 is a cryogenic probe socket designed to operate seamlessly in extreme environments. But what truly sets it apart is its adaptability and precision. Unlike anything before it, the PQ500 is cryostat-agnostic, meaning it integrates effortlessly with both FormFactor and third-party systems. Its cryogenic vertical MEMS probes, capable of 150 µm pitch probing, ensure flawless contact between the probe tips and the pads, even as temperatures plunge to mK levels.

It’s not just about surviving these conditions, it’s about thriving in them. By delivering real silicon performance data without the need for packaging, the PQ500 helps researchers and manufacturers achieve more in less time. The results? Faster development cycles, lower costs, and a clear path to scalability.

The impact of the PQ500 is already being felt. Researchers at Kobe University recently demonstrated its ability to transform testing workflows:

- Conductivity Amplified: As temperatures dropped from room temperature to 4 K, the resistance in tested devices fell by 65%, showcasing improved conductivity that’s critical for quantum IC functionality.

- High-Frequency Performance Secured: The PQ500 maintained exceptional electrical performance, with minimal insertion loss even at 20 GHz, proving its reliability for cutting-edge applications.

- Precision Perfected: The active alignment system allowed engineers to achieve micrometer-level accuracy, ensuring consistent results across temperature transitions.

These achievements underscore the PQ500’s role as a game-changer in the quantum space, enabling testing solutions that were once deemed impossible.

Looking Ahead

Innovation doesn’t stop at success. At FormFactor, we’re already working to enhance the PQ500’s capabilities, from supporting smaller pad pitches to enabling even higher testing speeds. Our goal is simple yet ambitious: to stay ahead of the industry’s evolving demands while empowering our partners to do the same.

Quantum computing’s future hinges on solutions that can keep pace with its exponential growth. With the PQ500, we’re not just meeting that need—we’re setting the standard.

Every breakthrough in quantum computing starts with a single test. It’s the moment we verify that a chip is ready to scale, that a new application can work, that an idea can become reality. The PQ500 doesn’t just perform these tests; it transforms them, making it faster, cheaper, and more reliable to take quantum innovations from concept to market.