In today’s fast-paced tech landscape, staying ahead with accurate device characterization is vital. RF wafer probing is a critical method for understanding the intrinsic properties of semiconductor devices, setting the stage for successful product development and manufacturing. This blog dives into the fundamentals of RF on-wafer measurements, the types of probers available, and best practices for achieving precise results.

Why RF On-Wafer Measurements Matter

RF on-wafer measurements offer a clear advantage: assessing a device in its raw, unpackaged state. This helps engineers pinpoint defects early, reducing costs and streamlining production with automated testing that ensures speed and accuracy. Without these measurements, packaging and assembly could obscure performance issues, leading to wasted resources.

Types of Wafer Probers

Selecting the right wafer prober is crucial for matching your application’s needs. Here’s a breakdown:

- Manual Probers: Ideal for research environments and educational institutions. These probers are budget-friendly but demand operator expertise for precise outcomes. They’re best suited for low-volume, high-flexibility applications.

- Semi-Automatic Probers: Featuring automated XYZ beta movements, these systems enhance measurement repeatability and accuracy. They often include features like automatic thermal drift correction, balancing manual flexibility with automation’s precision.

- Fully Automatic Probers: Equipped with wafer loaders, these probers shine in full-scale production. They facilitate continuous testing of entire wafer lots, enabling 24/7 operation with minimal oversight.

Key Components of an RF Measurement Setup

To conduct reliable RF measurements, a carefully assembled setup is essential:

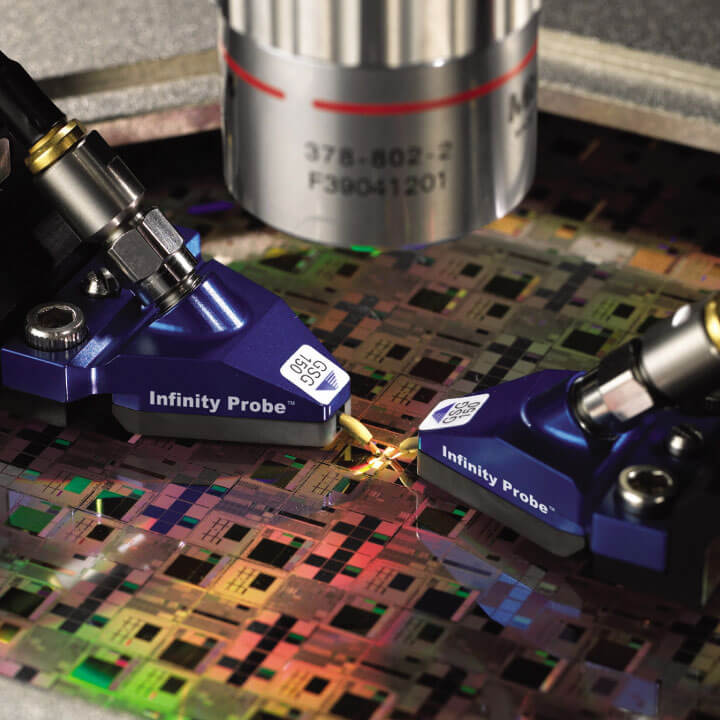

- RF Probes: These bridge the coaxial cable environment to the coplanar environment of the device, minimizing signal loss and maintaining low contact resistance.

- Power Source & Network Analyzer: A stable power source ensures biasing, while a vector network analyzer (VNA) measures critical parameters.

- Cabling & Calibration Software: Cables connect the VNA to probes, while advanced calibration software fine-tunes measurement accuracy through complex algorithms.

The Role of RF Probes

RF probes are indispensable for a seamless signal transition. Specially designed to minimize electromagnetic interference, these probes cater to a wide range of applications and materials, including challenging surfaces like aluminum. The ACP series, Infinity series, and T-wave probe series exemplify versatile solutions tailored for different frequency ranges and testing conditions.

Ensuring Calibration and Accuracy

Accurate RF measurements hinge on rigorous calibration. Without this step, errors such as directivity, transmission tracking, and reflection tracking can skew results. Here’s an overview of popular calibration techniques:

- SOL (Short-Open-Load) Calibration: Ideal for one-port measurements, this method corrects system errors using three standards: short, open, and load.

- SLT (Short-Load-Through) Calibration: Suitable for two-port setups, offering more comprehensive correction.

- LRM (Line-Reflect-Match) Calibration: A simpler yet effective technique requiring fewer assumptions about standards, making it easier to implement and highly reliable.

Thermal Management and Automation

Temperature fluctuations can lead to inaccuracies during testing. Probers equipped with thermal management systems adjust probe spacing and recalibrate to maintain accuracy as temperatures shift. This automation enhances reliability and allows for continuous, unsupervised operation—saving costs and boosting efficiency.

Mastering RF wafer probing requires understanding the types of probers, the components of an RF measurement setup, and the importance of calibration and thermal control. By investing in appropriate systems and maintaining rigorous procedures, manufacturers and researchers can achieve high precision and reliability in their device measurements.

For more insights and in-depth discussions, don’t miss our on-demand webinar: Watch Now.