The push for better energy efficiency in systems, vehicles, consumer appliances, portable electronics, and new integrations with the Internet of Things is fueling ongoing improvements in power semiconductor devices, leading to an annual increase in demand that consistently reaches new record highs.

Consequently, companies and foundries worldwide are expanding their testing capabilities in R&D, production of high-performance devices, and high-volume general manufacturing. Efforts to develop next-generation power devices are accelerating, aimed at reducing costs for end-users and meeting the diverse performance requirements of expanding applications.

In the sectors of electric vehicles and transportation, the demand for power semiconductor devices/modules is on the rise. These applications call for devices that can handle higher currents (200 – 400 A) and voltages (3.3 – 10 kV) at increased temperatures (300 – 400°C) to adhere to new standards of reliability and performance. This necessitates comprehensive R&D for device characterization and the development of testing methods.

Engineers are particularly challenged by the need to perform tests on the wafer itself rather than after packaging. FormFactor is significantly contributing to advancements in on-wafer testing for power semiconductors.

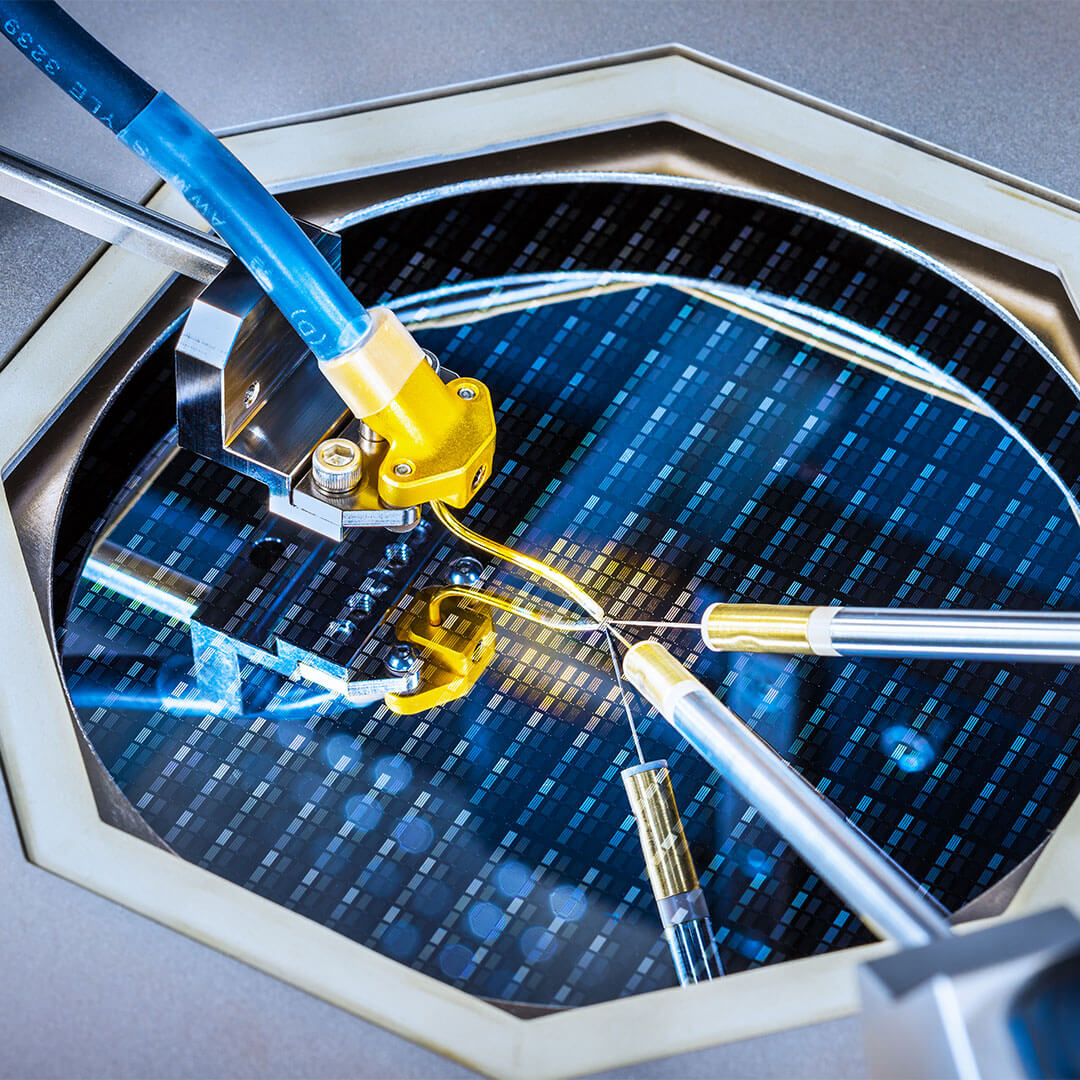

FormFactor has built the TESLA300, a cutting-edge On-Wafer Power Semiconductor Probing System designed for power semiconductor researchers, device/test engineers, and manufacturing managers/operators.

The TESLA300 facilitates the gathering of precise data on high voltage and high current measurements, ensuring total safety for operators. It supports testing on both individual and volume-thinned wafers for R&D, device characterization/modeling, and specialized production with maximum efficiency.

The TESLA300 Advanced On-Wafer Power Semiconductor Probe System is a comprehensive high-power testing solution that allows for the precise gathering of high-voltage and high-current data, achieving up to 3 kV (triaxial) / 10 kV (coaxial) and 200 A (standard) / 600 A (high current), while ensuring total safety for operators.

This system is equipped with lab automation features, facilitating high-power electrical measurements critical for device characterization, engineering at high volumes, and applications that present unique challenges. Additionally, the TESLA300 is perfectly tailored for custom solutions, specialized production needs, and burgeoning market sectors.

To complete its offering, FormFactor provides a wide selection of high-voltage and high-current probes, along with anti-arcing probe cards. The equipment supports high power testing for both engineering and production, available in manual, semi-automatic, and now fully-automatic versions, to achieve the quickest possible time to accurate data.