There are two significant challenges inherent with mm-Wave and terahertz (THz) measurements – insertion loss and measuring over temperature variations (hot and cold).

Insertion Loss Testing at mm-Wave and terahertz frequencies presents a significant challenge: elevated insertion loss within the measurement channel. As frequency increases, so does the difficulty of maintaining signal integrity. Traditional measurement setups, which work well at lower frequencies, often suffer from reduced dynamic range and directivity at these higher frequencies. This drop in performance can lead to inaccurate measurements and unreliable calibrations. Insertion loss is especially concerning because it degrades the signal before it even reaches the device under test (DUT), compounding issues related to noise and reflection. To counter this, test engineers must focus on minimizing loss through careful selection of cables, connectors, and other components in the signal path.

Measuring Over Temperature Variations (Hot and Cold) Temperature fluctuations create another critical challenge in mm-Wave and THz measurements. Probes, waveguides, and other components tend to expand or contract with thermal changes, which can shift alignment and alter the electrical properties of the test setup. For example, large frequency extenders and long waveguides are particularly susceptible to these variations, making it harder to maintain calibration accuracy across different temperature conditions. This shift can be problematic in both R&D environments and real-world applications where devices need to operate reliably across a range of temperatures. Keeping the measurement path as short and stable as possible is key to ensuring that these changes don’t compromise the quality of the data.

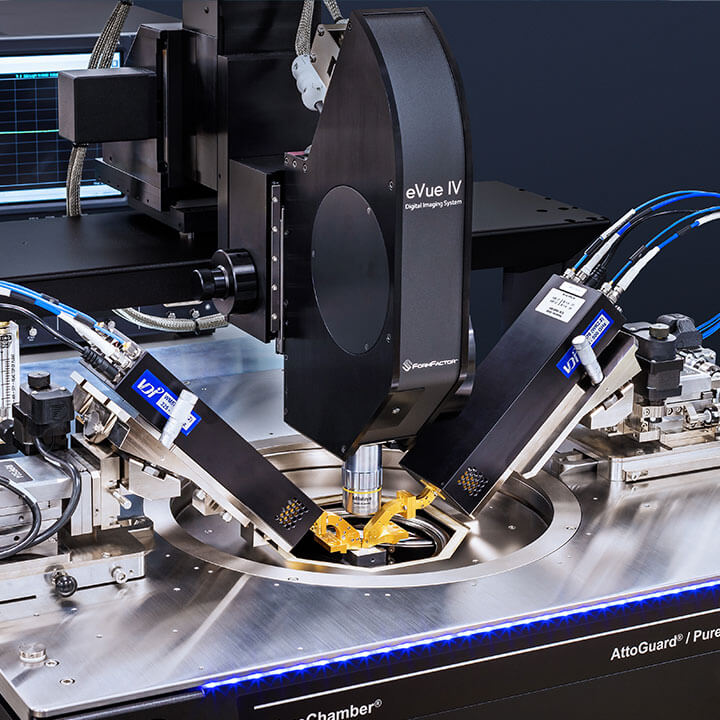

FormFactor’s modular on-wafer integration strategy for advanced mm-Wave and THz measurements is designed to tackle the challenges of testing over a wide temperature range. By positioning the frequency extenders as close to the wafer as physically possible, this approach minimizes the length of the signal path, thereby reducing insertion loss and improving overall measurement accuracy. Precise waveguide probing at these high frequencies is notoriously difficult, especially when factoring in temperature variations, as mentioned above. However, this modular setup ensures that signal integrity is maintained even as temperatures fluctuate from -60°C to +125°C. The result is highly accurate, repeatable data, allowing for more confident decision-making in device characterization and validation across a full thermal spectrum. This close proximity of components also helps mitigate the thermal expansion and contraction effects that can distort measurements, ensuring consistent performance during both hot and cold testing environments.

We take a comprehensive approach to wafer-level testing for mm-Wave and Terahertz devices, focusing on delivering a seamless, end-to-end solution. By collaborating with top-tier industry partners – Keysight Technologies, Virginia Diodes and DMPI – we combine the strengths of multiple experts in test technology to create powerful, integrated systems. Leveraging our deep expertise in automation and system integration, we engineer a complete solution that is ready to use, eliminating the need for additional development work on your end. Our approach not only simplifies the testing process but also helps you cut costs, accelerate testing timelines, and speed up your product’s journey to market.

The solution is available for the MPS150, PM8, Summit 12000/11000, SUMMIT200, CM300xi and Elite. 67 GHz and 110/120 GHz versions are available.

By incorporating our groundbreaking Autonomous RF Measurement Assistant to these probe stations the system allows for fully hands-free calibrations and measurements, significantly lowering testing costs while speeding up your time to market. This innovative solution is designed to work seamlessly with all FormFactor probe stations, whether manual, semi-automatic, or fully automated, ensuring flexibility and efficiency across different testing environments.

For more information on advanced mm-wave and terahertz measurement and the technologies designed to overcome its challenges, be sure to visit our website.