System calibration is critical to getting accurate measurement data from RF wafer devices.

During calibration, a set of known standards are presented to the tip of the probe. The level of our knowledge of these standards is a key consideration for advanced calibration techniques as it affects accuracy.

In the past for 4 port calibrations we have been limited to using methods such as Short Open Load Thru (SOLT).

In that approach, all standards must be completely known including the thru standards.

Probe positional variation on the load, short and open calibration standards will cause the electrical behavior to vary from the defined standard parameters, assuming accurate standard definitions are available. In addition, these parameters are generalized and will be subject to manufacturing tolerances themselves of probe and substrate.

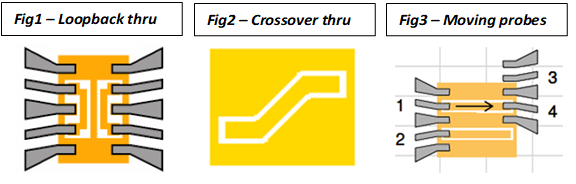

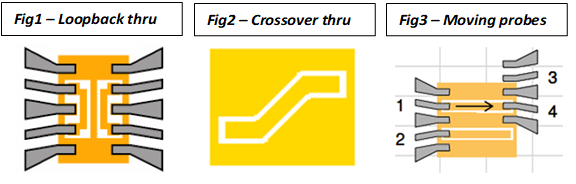

4 Port calibrations also have one additional issue. Two of the thrus, by virtue of the probe geometry, will either be a loop back (Fig1) which is the worst case or a crossover (Fig2) which in many cases isn’t present on existing substrates. Another alternative (Fig3) is to offset the probes in the Y axis which should give more ideal thrus but needs motorized positioners and involves some tips touching the bare substrate.

The thru behavior can vary significantly from the classical definition of these standards, and often existing polynomial approaches do not accurately describe them. All errors described will vary as a function of frequency.

Also, as the number of ports (N) goes up, more standards are measured. For the thru structures, the combinations can be proportional to N2. This large number of possible probe movements increase the risk of calibration error due to alignment variation. This all leads to errors in the calibration accuracy.

Our advanced 2-port line-reflect-reflect-match (LRRM) calibration technique has been widely adopted for on-wafer use for many years. The main advantages of this approach are that short and open reflects are unknown and thus less susceptible to probe misplacement due to scrub variation. Their main pre-requisite is that they are symmetrical. As for the loads this approach allows the load inductance to be calculated from optimization of the open reflects.

In addition, the SOLR calibration has been used for some time for circumstances where a well-defined thru simply isn’t available, but this technique still requires well defined reflects with inherent issues as described previously.

The beauty of SOLR-LRRM hybrid cals is that it builds on the best from both calibration methods – ie., unknown reflects, load inductance calculation and two unknown thrus.

With the 4 port approach, two of the thrus must be well defined but this is straightforward as they are traditional straight thru structures where the signal tips face one another.

However, two of the thrus only need to be reciprocal with a delay estimate – they can be somewhat non ideal and the cal will still be accurate, and this is the case for the loopback or cross over thru.

The hybrid LRRM-SOLR is provided in our WinCal XE calibration and accuracy enhancement software.