China International Semiconductor Executive Summit took place in Shanghai China from October 24-26. On the second day of the event, our SVP of Marketing and Customer Solutions Amy Leong hosted an advisory board panel discussion that touched on the growing China fabless market.

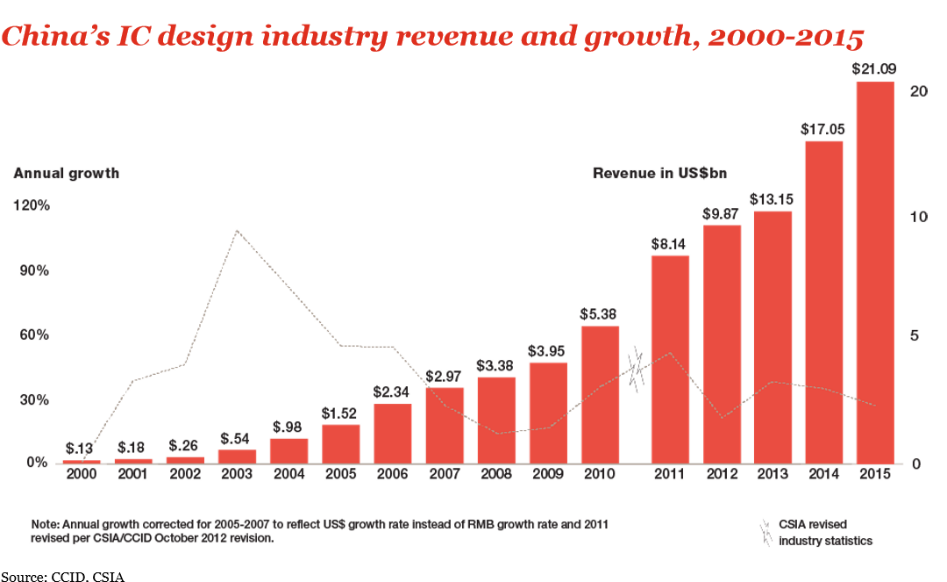

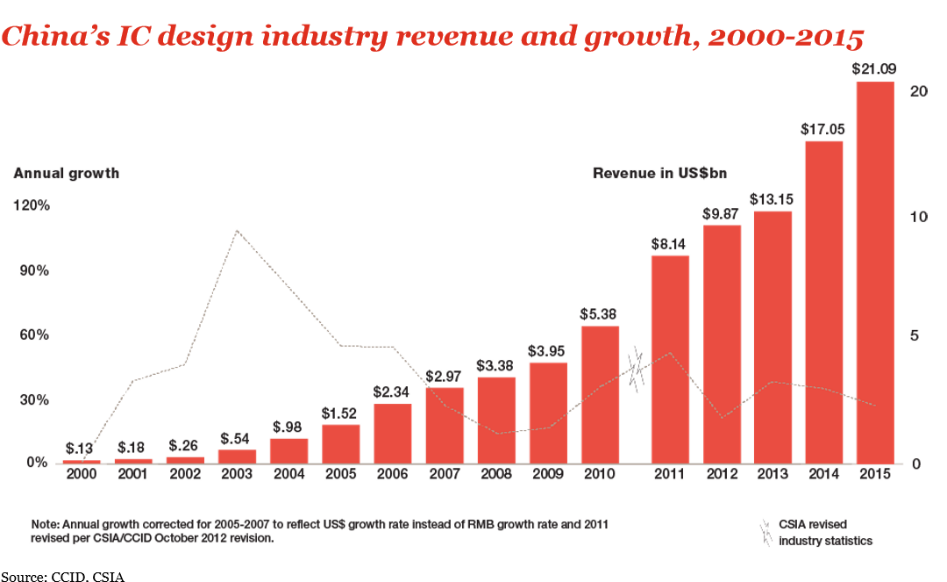

While there has been major consolidation in the semiconductor industry over the last few years, maturing at a growth rate that’s more GDP-like, China’s fabless semiconductor industry is growing much faster. The graph below shows China fabless company revenues over the last decade. From 2005 to 2015, the fabless revenue has grown at 30 percent CAGR, now contributing to 25% of worldwide fabless revenue.

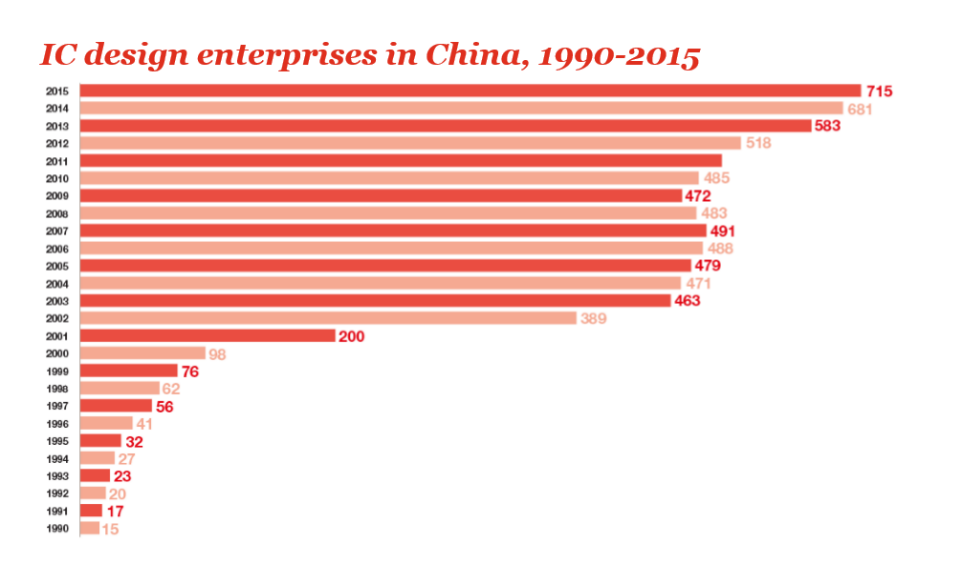

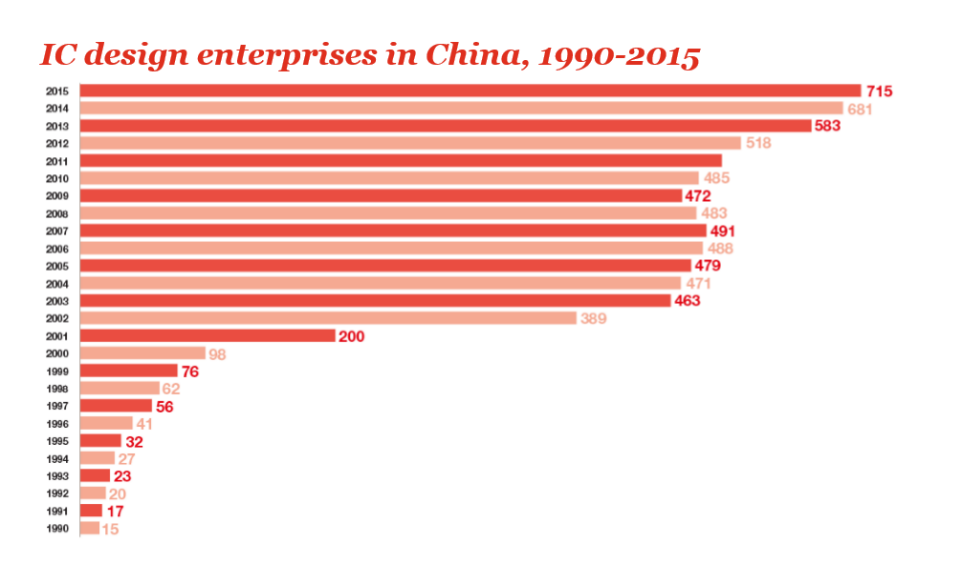

The graph below shows the number of China fabless companies. Back in 2010, when there were nearly 500 companies, the talk in the industry was how many would actually make it. In 2015, this number hit 700, and SEMI China President Mr. Lung Chu stated in his presentation at CISES that there are now over 1000 China fabless companies.

The executive panelists, including Dr. Xiaoning Qi (CEO of C-sky Microsystem), Chun Ya Chen (VP of Global Operations at IDT), Dr. Jun Zeng (CTO/EVP of MaxPower Semiconductor), Farhat Jahangier (VP Operations and Quality at Quantenna), and Carl McMahon (President/EVP Global Sales and Marketing at Genmark Automation), shared their insights.

So what’s different for the China fabless market?

- There are many talented engineers who want to be their own boss.

- There is a vast Internet of Things (IoT) market in China which doesn’t require leading-edge technologies.

- IoT is best developed by domestic companies for the domestic market. An example would be a smart-home device for China, which is clearly best developed in local language(s) and with a deeper understanding of the use patterns and habits.

What are some challenges and opportunities for the China fabless market?

- How to find and retain the right talent. Many of the fabless companies are funded by foreign-trained and educated management. China’s new engineers will need a lot of training to be highly effective.

- How to improve productivity. A workable solution identified by the panel is to provide experienced management to train employees. An example would be how to run efficient meetings with a clear agenda.

How can vendors better support the growing fabless companies?

- Better collaboration to achieve lower costs. China semiconductors will continue to be cost-sensitive due to the nature of the domestic end application. Vendors and companies need to work more closely to achieve lower costs through transparency (technical and business metrics).

- Localize manufacturing as a real long-term solution for efficient logistics. This can help eliminate issues with products getting stuck in customs during importing and exporting, for example.

This year’s conference was very educational, and we look forward to participating again in the future.