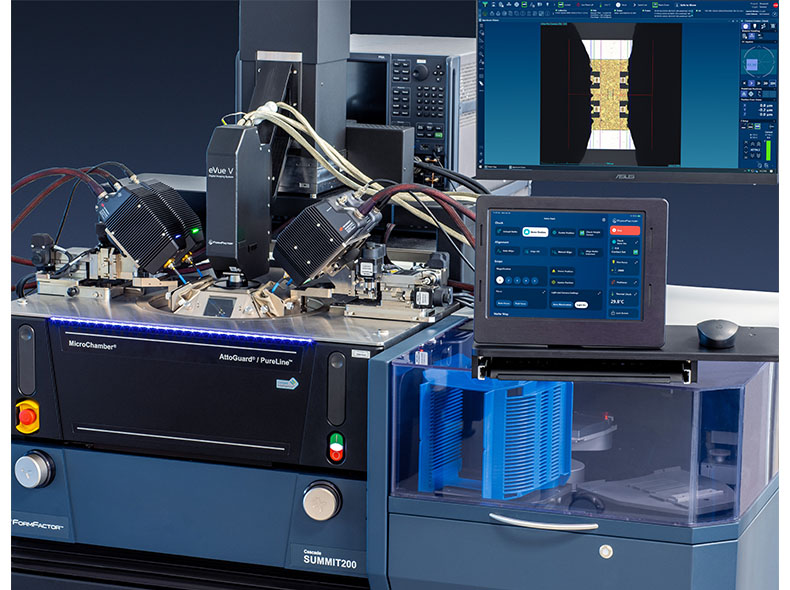

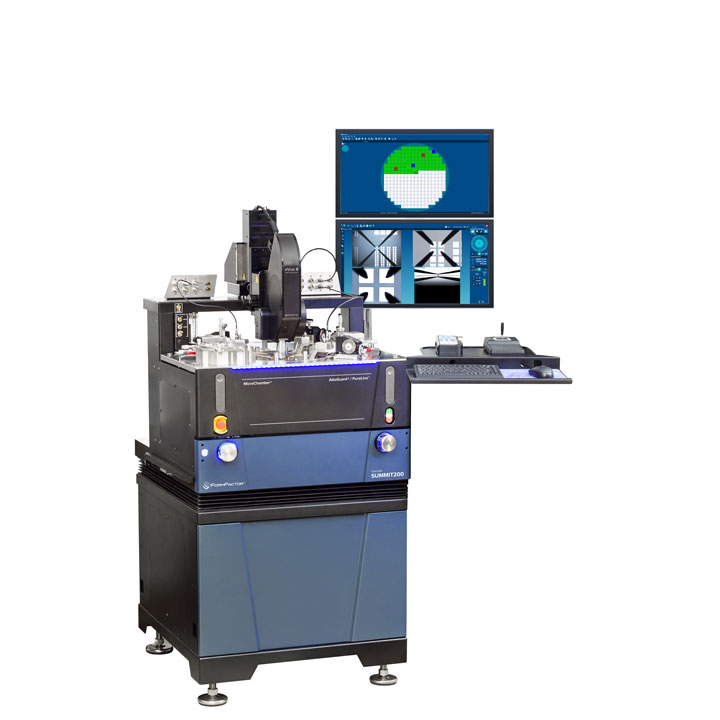

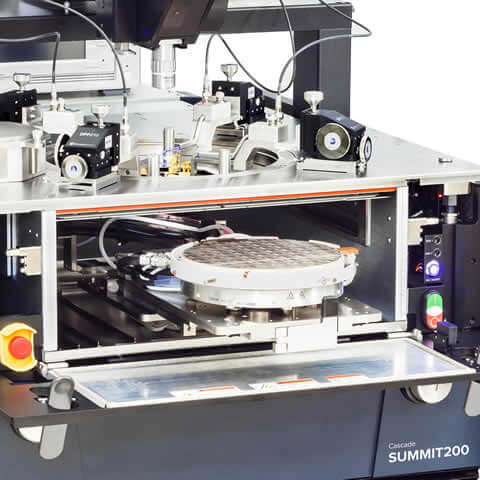

SUMMIT200

Advanced 200 mm semi-/ fully-automated probe system

Advanced 200 mm semi-/ fully-automated probe system

Looking for customer support? Ready to learn more about our products and services?

Contact Sales TodayReceive product updates and event notifications

Subscribe to Our Newsletter

200 mm Probe Station for Collecting High-accuracy Measurement Data up to 5X Faster

The new Cascade SUMMIT200 advanced 200mm probe system, is essential for collecting high accuracy measurement data on single or volume wafers; as fast as possible.

Designed for R&D, device characterization/modelling or niche production applications, the SUMMIT200 probe station enables precision electrical measurements over temperature for ultra-low noise, DC, RF, mmW and THz applications, with semi-automatic and now fully-automatic operation, for fastest time to accurate data.

A new advanced 200 mm fast stage, cassette handling up to 50 wafers, high throughput test features, and wide temperature range of -60°C to 300°C in both closed and open environments with FormFactor’s IceShield™, provides everything needed for the scientist, R&D and test engineer, or production operator to get their job done fast.

The next generation probe system supports PureLine™ technology to achieve one of the lowest noise levels available on the market. Patented AttoGuard® and MicroChamber® technologies significantly improve low-leakage and low-capacitance measurements. A new advanced 200 mm fast stage, cassette handling up to 50 wafers, high throughput test features, and wide temperature range of -60°C to 300°C, provides everything needed for the scientist, R&D and test engineer, or production operator to get their job done fast.

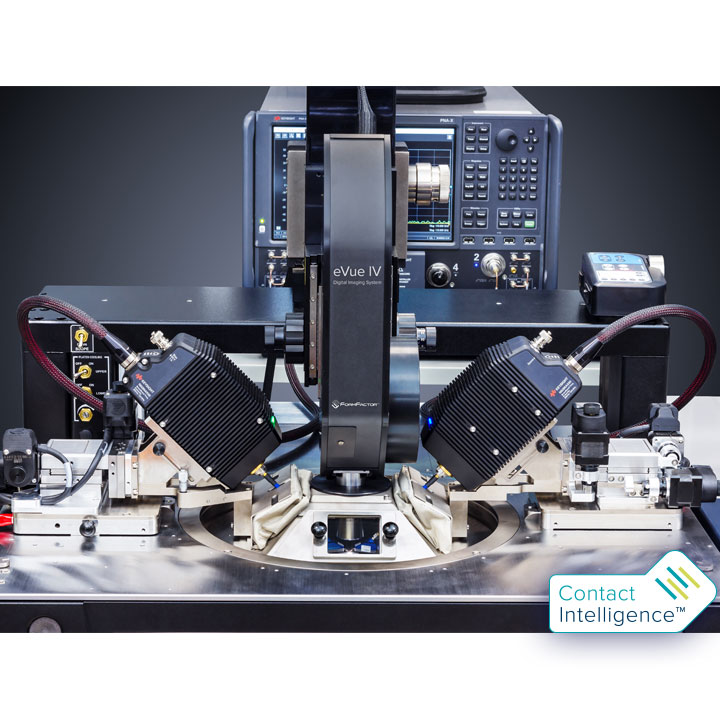

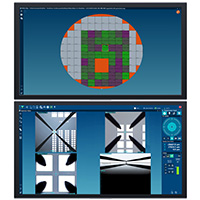

The SUMMIT200 probe station supports Contact Intelligence™ – a unique technology which enables autonomous semiconductor test. A powerful combination of innovative system design and state of the art image processing provides an operator-independent solution to achieve highly-reliable measurement data at any time and temperature.

With a wide range of applications, and upgrade paths to meet any future needs, the SUMMIT200 provides the most advanced 200 mm probe station platform for fast, high accuracy and high-volume measurements for existing and future devices and ICs.

*The SUMMIT200 platform is also available in different versions for measurement tasks that do not need the enhanced feature set as described above. Please refer to Data Sheet for details and options.

SUMMIT200 Advanced Probing System

Designed for R&D and device characterization/modelling applications, the SUMMIT200 enables precision electrical measurements over temperature for DC, RF, mmW and THz applications, with semi-automatic operation for fastest time to accurate data.

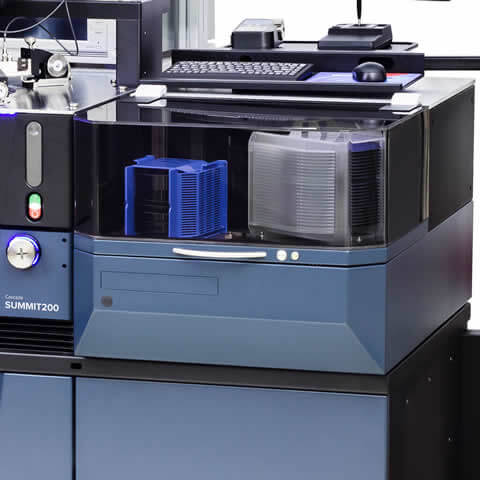

SUMMIT200 Probe Station – Manual and Fully Automated Wafer Handling

FormFactor’s SUMMIT200 advanced 200 mm probe station enables fast and precise SEMI-compliant wafer handling, both manual and fully automated.

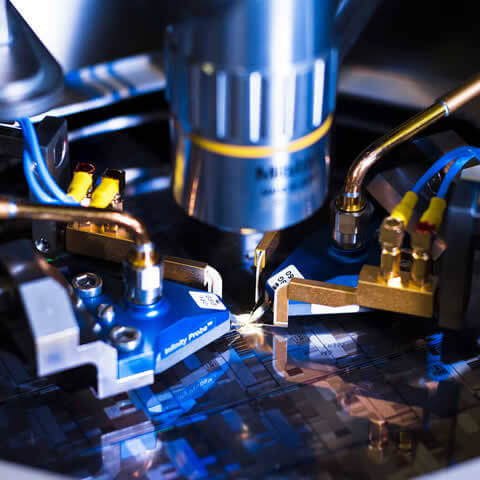

Automated Wafer Probing with Vertical Probe Cards on the SUMMIT200 Probe

FormFactor’s ReAlign™ technology for the SUMMIT200 wafer probe station enables automated probe-to-pad alignment for applications with limited microscope view such as vertical and Pyramid probe cards.

Autonomous DC Measurement Assistant

FormFactor’s Autonomous DC Measurement Assistant enables true hands-free 24/7 wafer probing over temperature and on small pads down to 30 µm. It reduces cost of test and increases throughput by automatically aligning probes-to-pads and managing thermal transition and soak times – without any operator intervention. By dynamically controlling each probe touchdown Auto DC improves test data with optimized contact resistance. Auto DC enables remote operation from home or anywhere in the world.

Autonomous RF Measurement Assistant

FormFactor’s Autonomous RF Measurement Assistant is the only solution in the market that enables true automatic, hands-free calibration and measurement of RF devices at multiple temperatures.

Autonomous RF Calibration and Wafer Probing Over Temperature at High Frequency

Anthony Lord, Director of the RF Market Segment at FormFactor Inc., demonstrates autonomous calibration monitoring and re-calibration over multiple temperatures at frequencies up to 330GHz.

170 GHz / 220 GHz Broadband Vector Network Analysis Solution

FormFactor, Keysight Technologies, DMPI, and Virginia Diodes, have joined forces to deliver a new 170 GHz / 220 GHz Broadband Vector Network Analysis (VNA) Solution that shortens design and verification cycles for 5G and emerging 6G applications.

220 GHz Broadband On-Wafer Probing System

FormFactor's 220 GHz Broadband On-Wafer Probing System shown at the European Microwave Week Symposium. FormFactor’s Giancarlo DeChirico and Gavin Fisher guide the tour and outline the system’s features and benefits.

Remote Wafer Probing with Autonomous RF

FormFactor demonstrates remote wafer probing at high frequencies and over temperature, showing automatic calibration and remote operation at EuMW 2022 in Milan.

Broadband S-parameter Measurement to 130 GHz | Anthony Lord

FormFactor RF Market Director Anthony Lord reviews the challenges of making very high frequency measurements over a broad band, especially at millimeter waves. He discusses the need for device modelling and circuit characterization with high accuracy and repeatability, as well as the challenges of making these measurements over temperature (-40 to as high as +175 degrees C).

Load-Pull Tuning with FormFactor’s CM300xi and Focus Microwave’s Low Frequency DELTA Tuners

Focus Microwave’s new low frequency DELTA tuners have been seamlessly integrated onto FormFactor’s CM300xi automated wafer probe station. The solution provides high VSWR fundamental and harmonic tuning and covers a wide frequency range of 1.8 to 40 GHz.

Turnkey Solution for Load-Pull Modeling and Characterization of 5G Devices and Transistor Circuits

FormFactor has partnered up with Focus Microwaves and Keysight to provide the most advanced turn-key solution for high-frequency fundamental and harmonic load pull measurements up to 110 GHz.

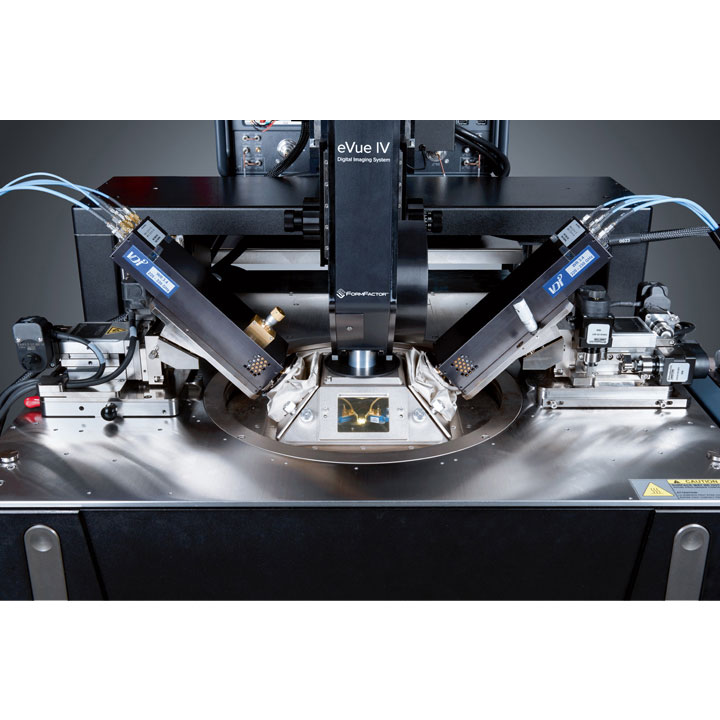

eVue IV Microscope

The eVue IV digital imaging system combines extraordinary optical performance with increased productivity.

SourceOne – Certified Pre-Owned Equipment

You want the best price-performance ratio for your wafer probe station? With our Certified Used Equipment we have an attractive option for you.

SourceOne – Factory Refurbishment Program

Extend the use of your probe station for up to another 15 years with our Factory Refurbishment Program.

SourceOne – Trade In / Buy Back Program

We'll take your probe station back for a credit note.

Receive product updates and event notifications

Subscribe to Our Newsletter